| TECHNICAL SPECIFICATIONS | |

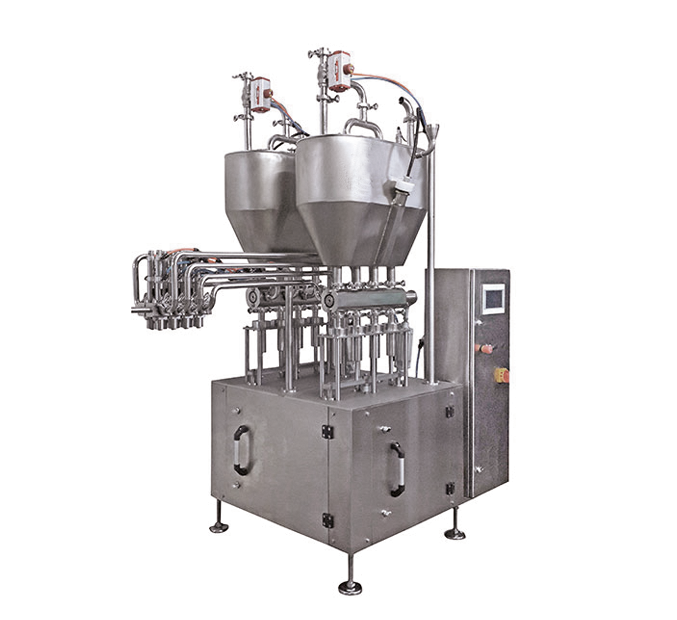

| Machine code | OMR-4 |

| Capacity | 5500-6000 ad/Sa |

| Bottle sizes | Min.40-Max.118 |

| Bottling Weight | Min 10gr-Max 1000gr |

| Air pressure | 6-8 bar |

| Electricity consumption | 380W -1.5 kw |

| Materials | 304-316 stainless steel |

| MACHINE SPECIFICATIONS | |

| Cup Dropping | |

| Filling | |

| Capping | |

| Sealing | |

| Dating | |

| Cup output | |

| OPTIONS | |

| Cabin | |

| Hepa Filter | |

| İnkjet | |

| Filling System – Servo Motor Flowmeter pneumatic | |

| Automatic Jeep System | |

| UV light-for bottles and caps | |

| Multi-cup capability |

APPLICATION AREAS

Used for filling the packaging of products such as Ayran, Yoghurt, Fruit Yoghurt, Water, Milk, Cream, Cream Cheese, Fruit Juices, Cheese, Honey, Gel, Pudding, Marmalade, Margarine, Butter, etc.

WORKING PRINCIPLE

Our machinery is set into motion by mechanical gearbox actuated by motor and reducer and rotates the rotary table on it. First cups are dropped in the chambers of rotary table from the cup dropping magazine and rotary table conveys the cups to the filling station. Our Cup Filling and Capping Machine must be aware that cups are complete before starting the filling; therefore, there is a sensor which senses every each chamber, in case of missing cups, then that nozzle will not start filling. Then filled cups are conveyed to top aluminum folio/cap placement station and here aluminum folios/caps are placed on the cups, which are then conveyed to sealing station. In this station, sealing is applied by adjusting temperature and time settings. After cups are sealed, they are dated in the next station and they are transported to next station for cup collection, here cups are uplifted to the level of conveyor by a piston and then they are conveyed on a belt conveyor by another piston. In the belt system, personnel can pick up the products to line up them on cup trays.

Bottling lines consists of several machines and bottles are automatically and linearly conveyed from one machine to another.

These machines are

-Bottle alignment machine-Bottle washing machine-Filling machine-Capping machine

-Labelling machine, etc.

The same machines can be used for filling and packaging different products.

-Machines are used in filling and packaging the products such as milk, ayran, water, fruit juice, ketchup, mayonnaise, cleaning materials.

- General Properties

-

TECHNICAL SPECIFICATIONS Machine code OMR-4 Capacity 5500-6000 ad/Sa Bottle sizes Min.40-Max.118 Bottling Weight Min 10gr-Max 1000gr Air pressure 6-8 bar Electricity consumption 380W -1.5 kw Materials 304-316 stainless steel MACHINE SPECIFICATIONS Cup Dropping Filling Capping Sealing Dating Cup output OPTIONS Cabin Hepa Filter İnkjet Filling System – Servo Motor Flowmeter pneumatic Automatic Jeep System UV light-for bottles and caps Multi-cup capability - Working Prenciple

-

APPLICATION AREAS

Used for filling the packaging of products such as Ayran, Yoghurt, Fruit Yoghurt, Water, Milk, Cream, Cream Cheese, Fruit Juices, Cheese, Honey, Gel, Pudding, Marmalade, Margarine, Butter, etc.

WORKING PRINCIPLE

Our machinery is set into motion by mechanical gearbox actuated by motor and reducer and rotates the rotary table on it. First cups are dropped in the chambers of rotary table from the cup dropping magazine and rotary table conveys the cups to the filling station. Our Cup Filling and Capping Machine must be aware that cups are complete before starting the filling; therefore, there is a sensor which senses every each chamber, in case of missing cups, then that nozzle will not start filling. Then filled cups are conveyed to top aluminum folio/cap placement station and here aluminum folios/caps are placed on the cups, which are then conveyed to sealing station. In this station, sealing is applied by adjusting temperature and time settings. After cups are sealed, they are dated in the next station and they are transported to next station for cup collection, here cups are uplifted to the level of conveyor by a piston and then they are conveyed on a belt conveyor by another piston. In the belt system, personnel can pick up the products to line up them on cup trays.

Bottling lines consists of several machines and bottles are automatically and linearly conveyed from one machine to another.

These machines are

-Bottle alignment machine-Bottle washing machine-Filling machine-Capping machine

-Labelling machine, etc.

The same machines can be used for filling and packaging different products.

-Machines are used in filling and packaging the products such as milk, ayran, water, fruit juice, ketchup, mayonnaise, cleaning materials.